Jetstream of Houston, LLP, a leading manufacturer of industrial high-pressure waterblasting equipment, parts and accessories, announces a new 40,000-psi model of its 4” J-Force™ pipe cleaning tool. Designed for durability, this self-powered rotating nozzle uses seven jets to clean and clear scale, hard carbon and polymer, sludge or other blockages in industrial pipes with 90-degree bends. The newest addition nearly doubles the cleaning power of the manufacturer’s 22,000-psi models and is ideal for tackling tough blockages. This new J-Force model joins a suite of size options that boost productivity and profitability while minimizing downtime and maintenance costs.

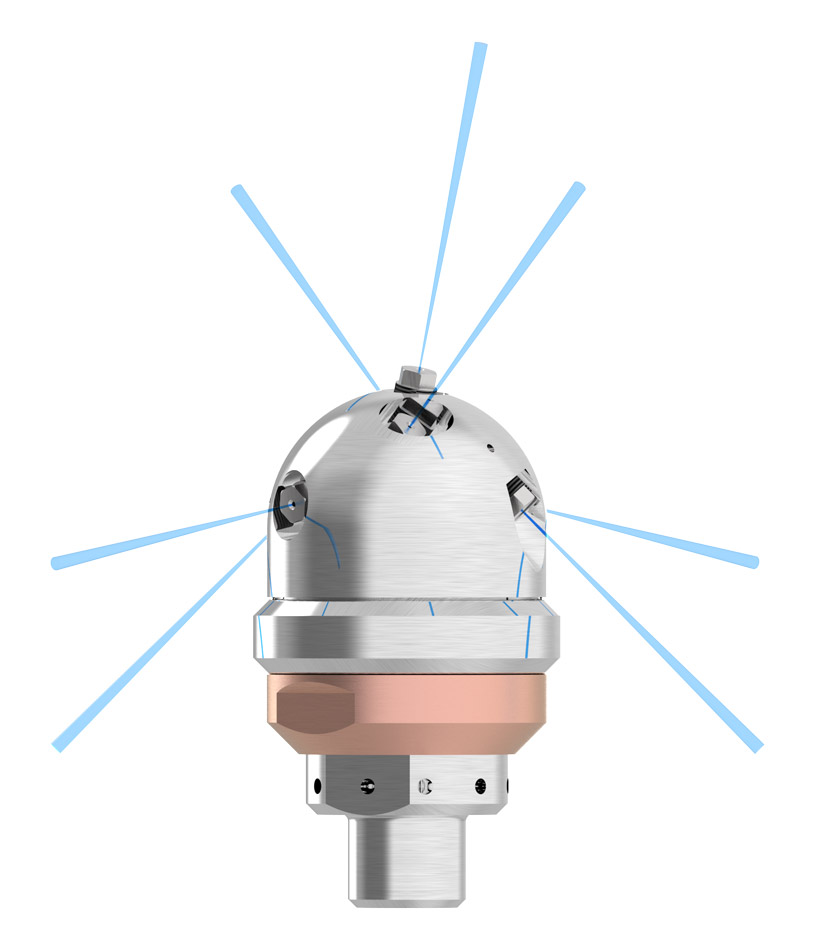

Jetstream’s J-Force features front, side, and rear jets that provide thrust to navigate the tool through the pipes as well as clean and clear blockages.

This signature tool operates with minimal maintenance thanks to Jetstream’s patented cartridge-style high-pressure seal design. This technology features permanently lubricated seal bearings to eliminate the need for oil and goes hand in hand with Jetstream’s eddy-current magnetic braking system. The 40,000 psi J-Force includes a replaceable wear ring to protect the body, and operators can replace seals quickly in the field with common hand tools. Combined, these innovations equip the J-Force to maximize uptime in the field by efficiently clearing blockages and providing a long wear life.

“Our customers often say inefficiency is their biggest cost, so we went to work on creating this 40,000-psi model of our popular J-Force tool,” said Jordan Koster, product and marketing manager for Jetstream. “The design and function of the J-Force reduces downtime and enables our customers to complete their jobs in half the time, and now we offer that efficiency for jobs that require higher operating pressures.”

The tool’s high performance also lies in the simplicity of its compact design. Whereas competing products have upwards of 20 or more parts, each J-Force has just 12 parts plus the nozzle inserts. Fewer parts mean a greatly reduced risk of costly repairs and less maintenance, especially considering that most models can be rebuilt in the field in less than five minutes. Jetstream’s patented seal cartridge technology streamlines the rebuild process.

The J-Force features front, side, and rear jets that provide thrust to navigate the tool through the pipes as well as clean and clear blockages. The tool is compatible with industry-standard inlet connections. The newest model, a second version of the 4-inch J-Force, can operate from 23,000-40,000 psi (1,500-3,000 bar), which delivers a powerful punch in removing buildup for a 360-degree clean. Additionally, Jetstream offers four size options to clean tubes as small as 2 inches (5.08 centimeters) and as large as 6 inches (15.24 centimeters) at up to 22,000 psi.

“Our philosophy at Jetstream has always been to maximize customers’ uptime by developing durable, reliable, and easy-to-use and maintain products,” Koster added. “By allowing our customers to focus on the job over maintaining the tools, our J-Force family delivers exactly that.”

For more information about the J-Force, contact Jetstream at 800-231-8192 or sales@waterblast.com. Learn more about our full product line.