Derc Salotech

MagTrack

MagTrack is an electrically driven modular system that is built around a universal carrier. The crawlers are designed to clean flat and slightly curved steel surfaces. Depending on the application, the page can easily be fitted with a full range of modular tools such as Swing Arms for open waterblasting or a Blasting Cap for vacuum sealed closed blasting. Rated for high-pressure water jets up to 40,000 psi (3000 bar).

Applications

- Surface preparation

- Oil storage tank cleaning

- Industrial cleaning and washing

- Cargo hold cleaning

- Abrasive blasting

- Inspection

- Waterjet cutting

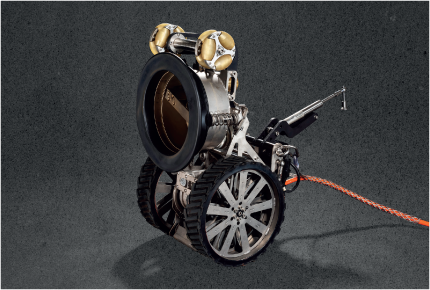

MagTrack Mini

The MagTrack Mini is a lightweight 2-wheel drive MagTrack. The compact crawler carries a fixed blast can (vacuum dome) which is used for “closed” water blasting. The blast can is connected to a vacuum unit so that both water and debris are collected without any leakage. The Blast Can is especially useful for industrial cleaning and preparation jobs where there is an absolute need to leave a clean and dry surface. Due to its lightweight and compact design, the MagTrack Mini is easy to transport and can be used in narrow spaces such as offshore oil rig surface prep. The MagTrack Mini can also clean pipes in a radial direction by replacing the flat vacuum seal with a curved seal. The MagTrack Mini is delivered with a remote controller, main control unit, antenna cable, magnetic antenna foot, and transport plate.

Features

- Compact design

- Two 48V electric drives

- Wheels with profile for maximum grip

- Height adjustable magnet

- ATEX zone 2 certified

- Main control box with 50m cable to carrier (optional ATEX)

- Dimension: 800x330x340 (fits through 24″ manhole)

- Weight: 45kg

Literature

* Available for rent only. Find an FS Solutions branch near you and talk to a representative to start your hydro-demolition job.

Swing Arm

Open Waterblasting

The Magtrack Swing Arm is used for open waterblasting, cleaning or sandblasting. It can easily be installed by one man on our 4-wheel magnetic carrier in under 30 minutes. The automatic drive mode can be controlled by adjusting the swing speed, drive speed and step size. Standard the swing arm is equipped with a swivel and a rotating manifold with pressure up to 3000 Bar. Other options are a fixed washing manifold or a holder for sandblasting. It is the perfect for industrial cleaning or surface preparation jobs, when it isn’t necessary to collect dirt or debris. A cost effective alternative to “closed” waterblasting, because there is no need for a vacuum pump.

Features

- Up to 140 m2 per hour cleaning capacity

- No need for vacuum supply

- Rotating manifold suitable for 8 inserts model type P/model 965

- Max 3000 bar @ 30 l/min

- Cleaning path: 1500 mm

- Dimensions: 925x217x750 mm (fits through 24” manhole)

- Weight: 20kg

Blast Can

Closed Waterblasting

The MagTrack Blast Can (vacuum dome) is installed in front of the 4-wheel carrier and is used for “closed” waterblasting. The blast can is connected to a vacuum unit, so that both water and debris is collected without any leakage. This makes the blast can especially useful for industrial cleaning and preparation jobs, when there is an absolute need to leave a clean and dry surface. For example the cleaning of (oil) storage tanks or the removal of old paint from ship hulls. Since the blast can is installed in front of the carrier, it also leaves a clean driving path for the carrier. This ensures the carrier won’t slip and stays even firmer attached to the steel surface.

Features

- Up to 120m2 per hour cleaning capacity

- Replaceable wear seal, under flexible bellow

- Adjustable vent valve for optimal extraction

- Rotating manifold suitable for 20 inserts model type P/model 965

- Atex zone 2 certified

- Optional LED lights

- Max 3000 bar @ 40 l/min

- Cleaning path: 370mm

- Dimensions: 685x630x450 mm (fits through 24” manhole)

- Weight: 25kg