Best Performing Nozzle in the Industry

John Benefield is the Industrial Services Supervisor at one of North America’s leading providers of environmental and industrial services. The company delivers a broad range of services, such as end-to-end hazardous waste management, industrial cleaning and maintenance, and recycling services.

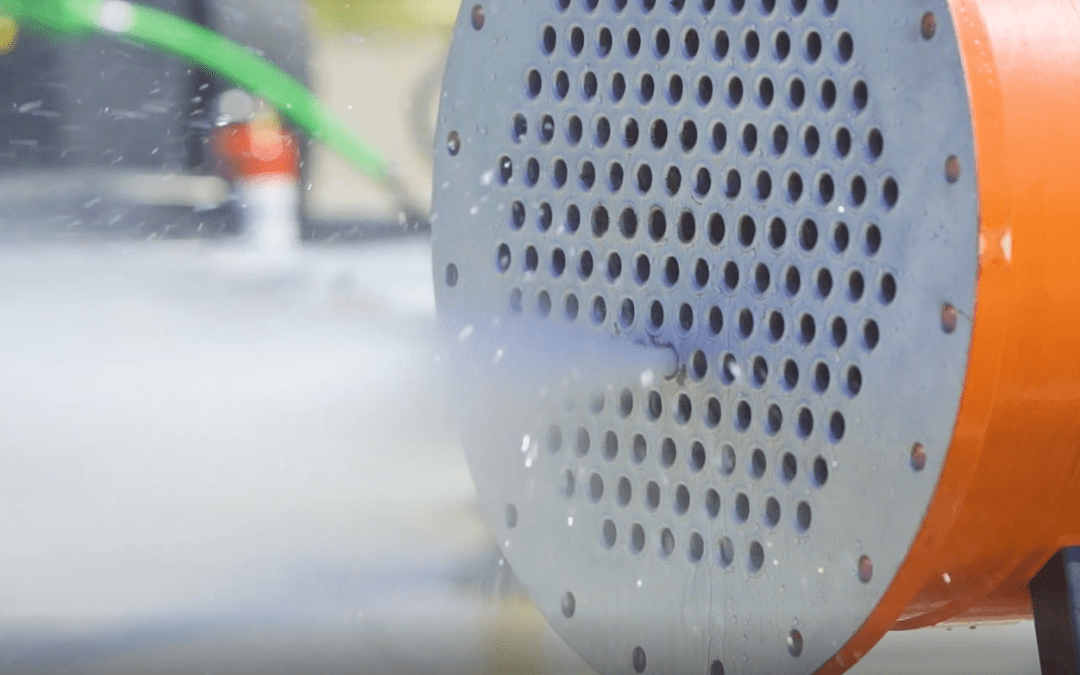

John oversees the routine cleaning of heat exchangers and tube bundles at an incinerator plant for a customer. Every two weeks, thick hydrocarbon collects in the tubes and builds up a large amount of flux. To clean the bundles, John and his crew primarily relied on another brand of nozzles. Frequently, the competitor nozzle would bump against deposits within the tubes, which caused the tool to get jammed and stop spinning. As a result, the team had to shut down the operation for hours at a time to repair the nozzle. After experiencing this issue for years and losing a lot of valuable time on the job, John knew it was time to re-evaluate the capabilities of the current nozzle, both in terms of cleaning performance and efficiency. John needed a solution that delivered superior performance and longevity in the extremes of tube cleaning applications.

Benefield kept those factors in mind when searching for a new solution. A customer since 2008, Benefield was familiar with Jetstream’s tools and services. After hearing about the all-new DrillJet tube cleaning nozzle and consulting his local representative, he decided to employ the tool.

“On the first day on the job, the team completely cleaned the tube bundle in just 1.5-hours using the DrillJet. When the team called to tell me they were finished, I could hardly believe it. We had gone from what normally took us 6-hours to 1.5-hours. The customer was ecstatic over how well the nozzle cleaned the bundle and the little amount of time it took,” said Benefield.

The DrillJet high-pressure nozzle is designed to clean and unplug heat exchangers and industrial tube bundles. Unlike competitors’ nozzle, the DrillJet features a powerful internal rotor protected by a rugged front cap. This front cap allows the nozzle to continue spinning even after hitting plugs, buildups, or other obstructions and was a key factor in the success of the cleaning job. The advanced design allowed the crew to efficiently and effectively clean the tube bundle without any interruptions, misalignments, or imbalanced spinning for improved cleaning performance and productivity.

Additional features of the DrillJet include advanced coatings for greater toughness, durability, and wear resistance. It is also 40% smaller than competing brands to easily maneuver through pipe bends. Beyond durability and reliability, the DrillJet offers a maintenance-free design to boost efficiency. The water-bearing technology eliminates the need for mechanical bearings, seals, or lubricants for reduced maintenance and increased cleaning production.

—-

“The DrillJet is a wonderful nozzle. It works extremely well to clean tube bundles and has helped us drastically cut cleaning time. If you’re in the industrial cleaning business, you need to try the DrillJet. It will save you a significant amount of time. “

– John Benefield

—-

The Jetstream DrillJet delivers the long life, reliable performance, and durability you need on the job. Currently available in 9.5mm and 13mm with additional sizes coming soon, the DrillJet supports working pressures up to 22,000 psi jet patterns.

For more information on the DrillJet, visit waterblast.com/drilljet or contact the Jetstream team at sales@waterblast.com.