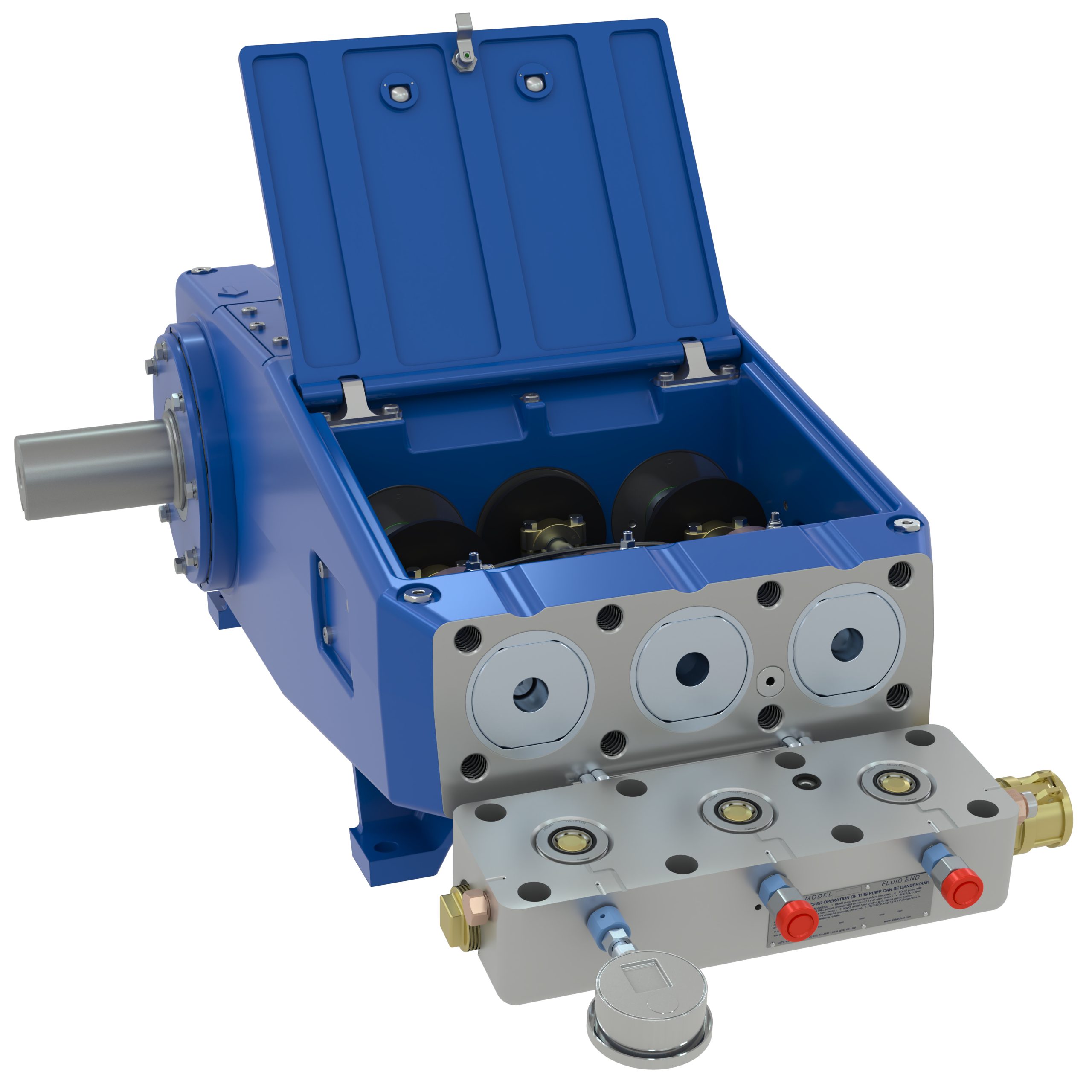

4200 UNx™

Pumps and Fluid Ends

Workhorse of the waterblast world

Well established as the reliable staple of industrial cleaning, the 4200 series of Jetstream pumps have the power to tackle difficult jobs and reliable performance that contractors and plants can count on. Quickly change between operating pressures for any Jetstream 3600 or 4200 UNx™ Pump with additional fluid ends. Conversions take only minutes and are available for pressures as low as 6,800 psi (469 bar) up to 40,000 psi (2750 bar).

The UNx™ Pump dominates the field with innovative American manufacturing, ductile iron power frames, heat-treated billet alloy steel crankshafts, and the largest bearings of any comparable pump.

Available on Jetstream’s X-Series waterblasting units or as a stand-alone pump for those building their system or replacing a complicated, worn, or unreliable pump.

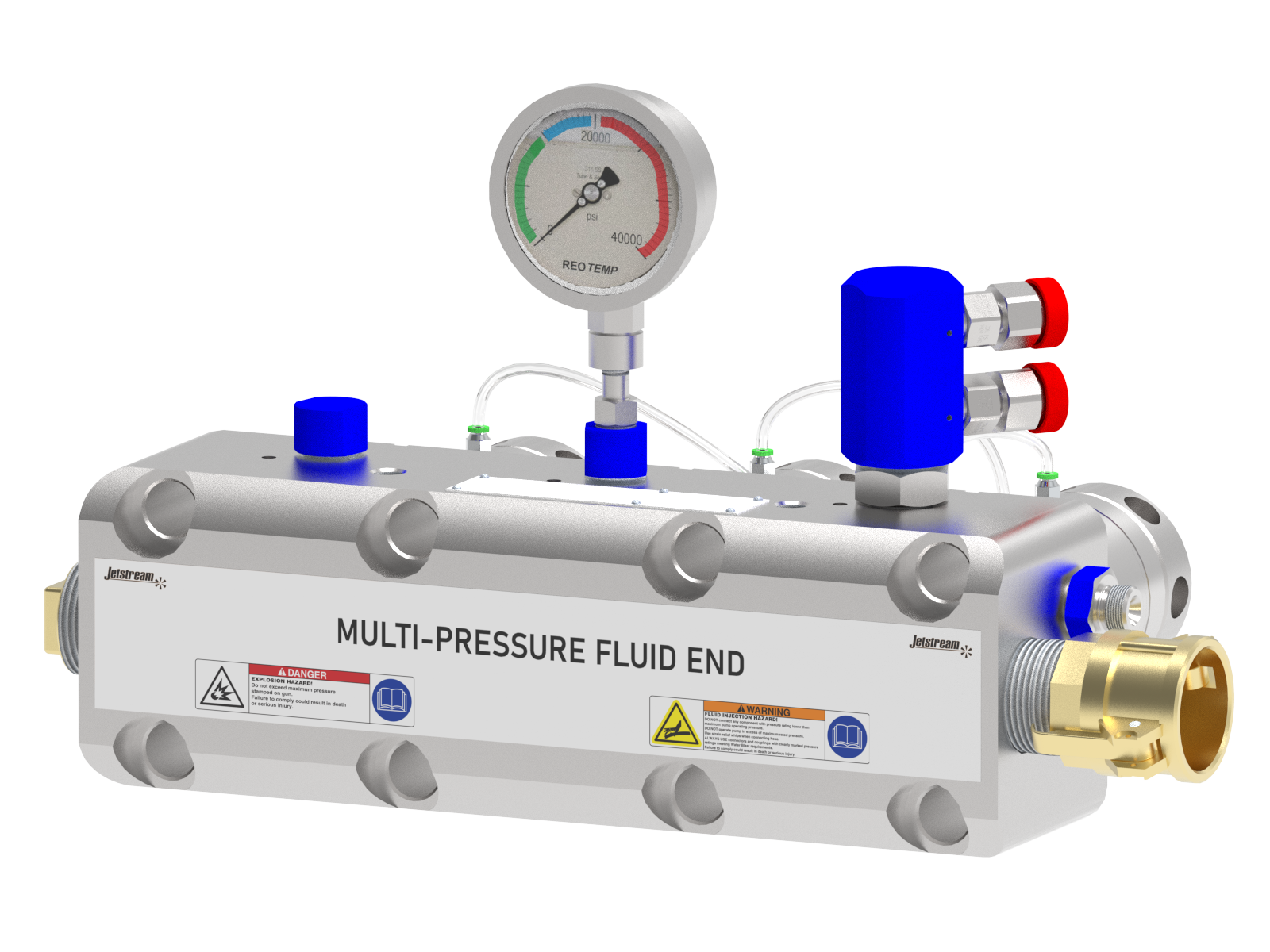

Combo Fluid End: Four Pressures. One Pump. No Compromise.

Introducing the Jetstream 4200 Combo Fluid End (CFE) — a next-generation, field-proven upgrade to our flagship 4200 Series. Designed for contractors and plants who demand flexibility without complexity, the CFE lets a single pump switch between 10K, 12.5K, 15K, and 20K psi in minutes using simple conversion kits.

Built on Jetstream’s trusted UNx™ platform, the CFE streamlines operations, simplifies spares, and maximizes uptime—without sacrificing power. Whether you’re handling pipe cleaning, surface prep, or tank blasting, you can now do it all with one fluid end.

Why Upgrade to the Combo Fluid End?

- One Pump, All Pressures: Switch between 10K–20K psi on the same pump in under 10 minutes—no full teardown required.

- Uptime Maximized: Quick-change UNx™ components cut downtime and eliminate unnecessary pump swaps.

- Simplified Inventory: Reduce spare parts and training complexity across your fleet with one versatile platform.

- Proven Performance: Engineered to meet Jetstream’s 20K psi standards with minimal flow trade-offs and rental-tested reliability.

- Future-Ready Efficiency: Lower total ownership cost by consolidating multiple fluid ends into one Combo Fluid End system.

Already using a Jetstream Gen II or Classic style fluid end? You can reuse your plungers, packing, and gland nuts—and Jetstream provides easy training and support to streamline your transition.

Key Specs

- Wide range of flow and pressure combinations

- Three plunger (triplex) design

- Plunger stroke length 4.25 in (108 mm)

- Max Power Input 325 HP (242 kW)

- 73.5 gpm at 6,800 psi (278 l/min at 469 bar)

- 11.9 gpm at 40,000 psi (45 l/min at 2750 bar)

- Max Frame Load 17, 750 ib (79 kW)

- Total weight 1800 lb (820 kg)

- Pump Oil Capacity 9 gal (34 L)

Key Features

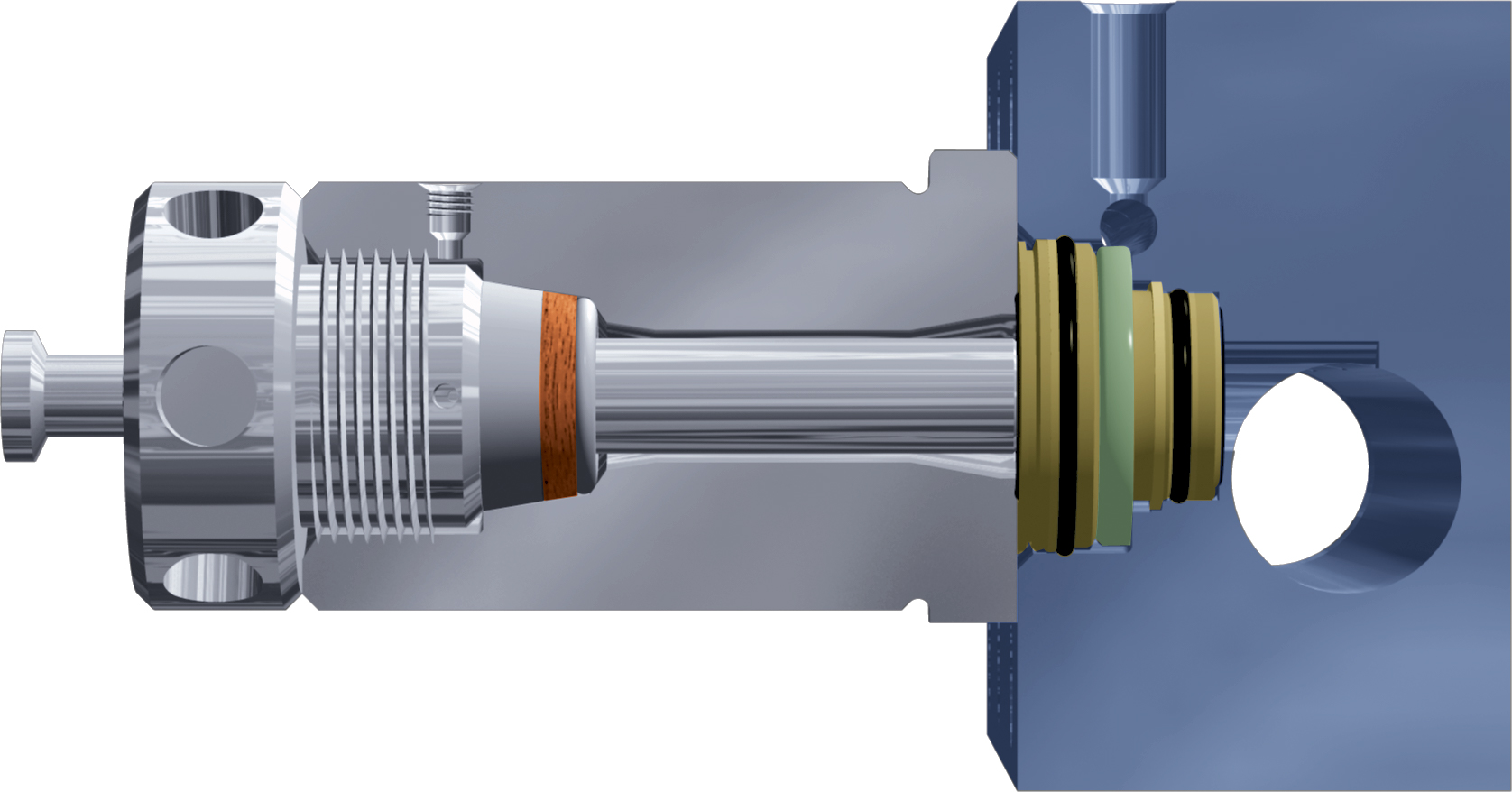

- Quickly change between pressures in the field with different Jetstream UNx™ Fluid End packages

- Reduced downtime and maintenance with quick change packing and valves

- Ductile iron power frame is the strongest in the industry

- Crankshaft machined from high-tech forged alloy for superior performance at higher power input

- Largest bearings of any comparable pump on the market

Contact Us

"*" indicates required fields